Automated Containerization: The Key to Fast, Efficient, and Sustainable Last Mile Fulfillment

Distribution, parcel, and e-commerce delivery networks, particularly for industry giants such as Amazon, UPS, and FedEx, are racing to meet same-day and next-day delivery promises. Sortation systems have evolved, robotics are advancing, and AI is reshaping upstream planning, but the final step before outbound often tells a different story. Containerization, whether in bags or totes, remains one of the most overlooked inefficiencies when evaluating throughput and meeting accelerating delivery demands.

What is Containerization in Distribution and Fulfillment?

At each stage of the supply chain, distribution facilities manage the inbound and outbound flow of products and parcels. Just as delivery vehicles are loaded with packages heading to the same destination, the same products are organized upstream into groups to efficiently route them at each step. Containerization is the process by which they are organized together as they navigate within a facility and to their next destination.

Containerization’s Role in Last Mile Delivery

Containerization plays a key role due to its impact on accuracy and efficiency. Many facilities rely on manual or outdated processes to handle this activity due to a lack of technologies that address the problem or the complexity of their operations. They also struggle to find equipment capable of fully automating sortation due to the volume and variety of packages handled.

The Evolution and Challenges of Automated Containerization

While many operations are manual today, automated conveyors and sortation equipment have helped solve part of the problem. Sliding shoe sorters, tilt tray sorters, and more can move and offload packages into designated areas. AGVs and robotics also handle some tasks, but can be challenging to integrate and are not always cost-effective.

And as packages approach outbound and last-mile delivery, the process gets increasingly manual. This results in additional labor and operational costs, mis-sorts, and ultimately lower customer satisfaction. Not to mention the impact of today’s labor shortage and retention challenges.

Companies, such as Amazon, are also pushing for sustainable practices that push the boundaries of efficiency while meeting increasing customer demand. These are nearly impossible to achieve without technological innovation.

Solving the Containerization and Last Mile Delivery Problem

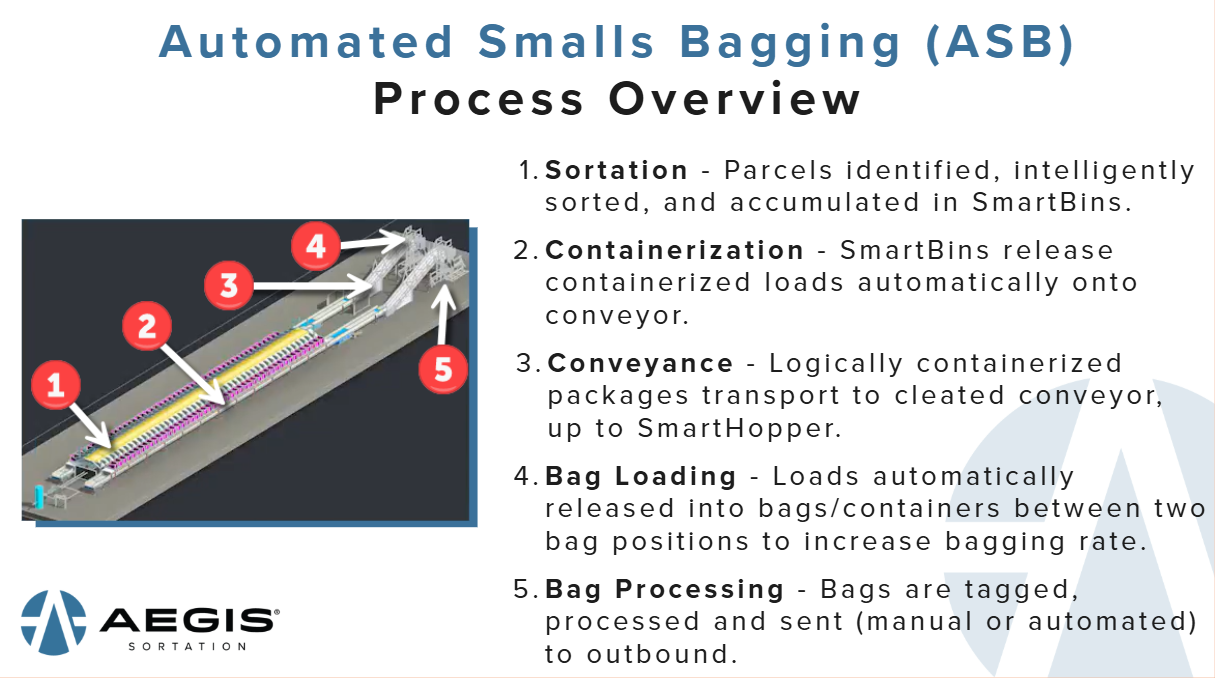

Revolutionary solutions like Aegis Sortation’s Automated Smalls Bagging (ASB) system solve these challenges with integrated systems that containerize and transport loads throughout the entire facility.

Packages are loaded onto a conveyor, which routes them to the appropriate sortation line. They are then automatically delivered to Aegis SmartBins by destination, where they are containerized, and intelligent programming determines when to release them onto a conveyor.

The conveyor moves them to the hopper, where they are loaded into bags. Aegis’ SmartBagger system automatically zips the bags and sends them to outbound.

With ASB, not only is the containerization process fully automated, it’s also optimized for throughput and efficiency while eliminating manual labor by as much as 50%.

Automated Smalls Bagging Advantages

Labor reduction: Automated bagging can cut manual effort by up to 50 percent, shrinking headcount needs and reducing overhead.

Consistent throughput: Automation keeps pace with sorter output, eliminating queues and re‑circulation.

Better ergonomics: Fewer lifts and repetitive motions mean less physical strain on workers.

Data visibility: Integrated sensors and software feed real‑time KPIs—bags per hour, fill ratios, exception codes—into WES dashboards.

Seamless Integration: Modular design allows ASB to be implemented at greenfield and brownfield facilities quickly and reduces line downtime during modifications.

What Success Looks Like in Last Mile Delivery

Automated containerization is the backbone that stitches together entire distribution operations. With automation, workers focus on higher-value tasks, managers see real-time KPIs, sustainability goals are met, and customer expectations are exceeded. It’s the practical step that turns great sortation into great delivery, and it’s where Aegis makes the difference.

Ready to See the Impact?

If you’d like to see how your distribution and last-mile delivery operations can be optimized, reach out to us today for an expert consultation. From our proprietary solutions to our industry-leading service and systems integration capabilities, we’re here to support your delivery operations from end-to-end.