Modular Automation: How Distribution and Parcel Hubs Modernize Without Shutting Down

In today’s parcel and logistics landscape, the pressure on hub and network operators has never been higher. Volumes climb, the parcel mix grows more unpredictable, and service expectations increase year after year. Industry analyses show that global B2C parcel volume surpassed 120 billion shipments in 2025, with continued year‑over‑year growth driven by e‑commerce and marketplace expansion

At the same time, major carriers are consolidating their networks, closing or merging facilities, and pushing more volume through fewer, smarter hubs while trying to avoid service disruption during the transition. Recent carrier transformation programs highlight just how delicate this balance is: operators must modernize fast, but operational downtime is simply not an option.

It’s no surprise, then, that modular automation has become the modernization strategy of choice for parcel and distribuuttion hubs that need to scale capacity, improve throughput, and reduce cost without taking their building offline.

At Aegis Sortation, we’ve seen this shift firsthand, including the impact of new rules governing network design, operational resilience, and facility uptime. Below, we break down why modular sortation is emerging as the smarter path forward, how leaders are executing retrofit projects without shutdowns, and where the industry is headed next.

Why Modernization Can’t Wait… and Downtime Isn’t an Option

Across parcel hubs, logistics centers, and increasingly in adjacent verticals like healthcare logistics, 3PL fulfillment, and high‑velocity retail DCs, operators are facing a culmination of operational challenges:

Rising parcel diversity. Industry data shows more polybags, irregulars, and lightweight items entering the network every year. This puts added stress on outdated systems originally designed for uniformity.

Facility consolidation. Several major carriers publicly reported station closures and network integrations in 2024 and 2025 as part of cost‑efficiency programs. These consolidations shift volume upward into fewer facilities that must immediately operate at higher productivity.

Peak‑season volatility. Forecasts for peak 2025 indicated more than 2.3 billion parcels moving through U.S. carriers in just a few weeks, with operators expected to absorb surges without missing service commitments.

Capital discipline. Operations want automation, but they want it in phases, not multimillion‑dollar, all‑at‑once overhauls.

Sustainability and regulatory pressure. Industry reporting shows increasing emphasis on energy‑efficient drives, quieter equipment, and intelligent power management.

Put simply: the network must evolve in a way that is scalable, non‑disruptive, and cost‑rational.

That’s where modular sortation stands apart.

“Operations want automation, but they want it in phases, not in multimillion-dollar, all-at-once overhauls”

Modular Automation That’s Built for Today’s Constraints

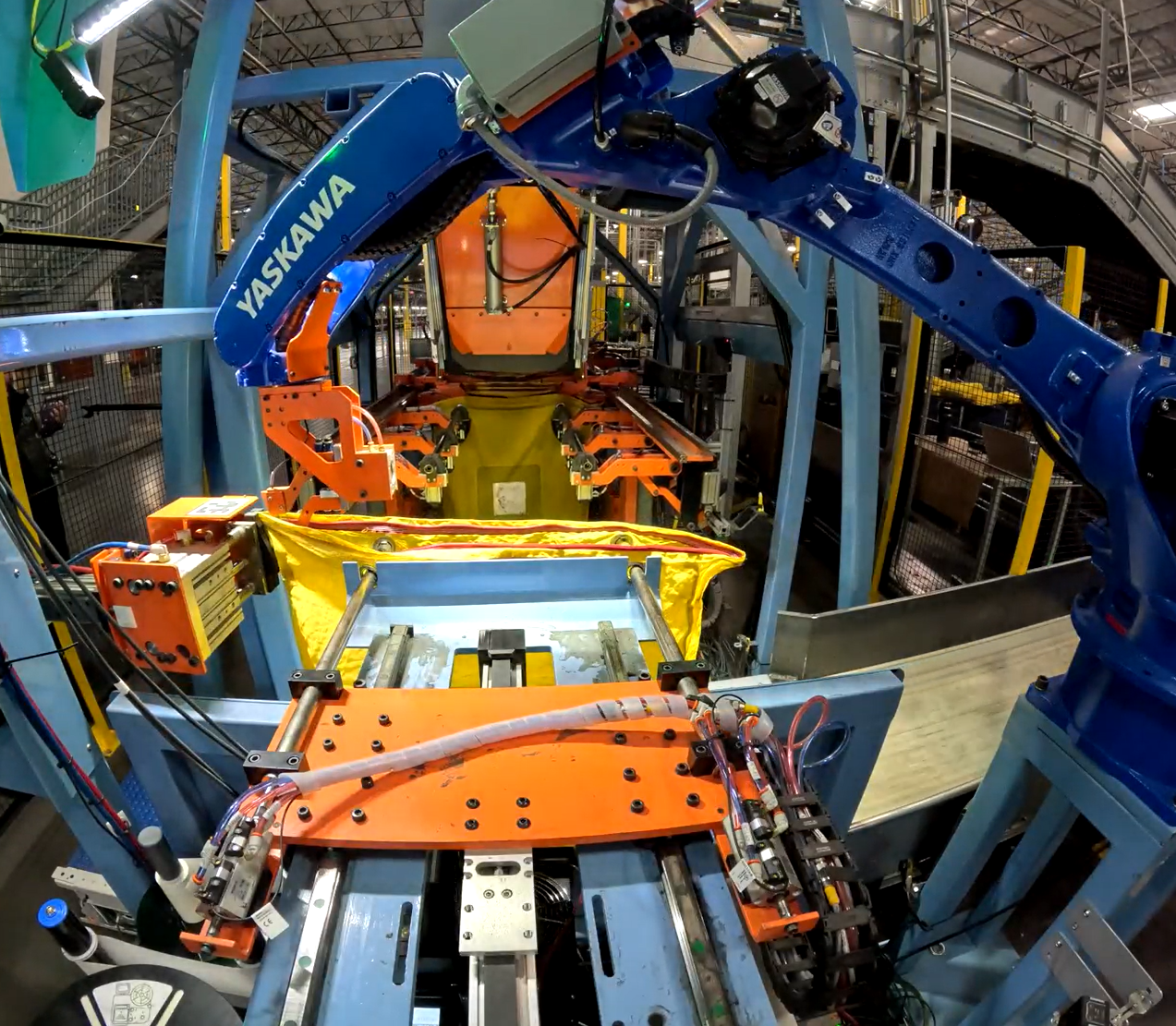

Modular automation and sortation systems, including steerable‑wheel tables, modular conveyor platforms, and incremental expansion kits, are designed for real‑world operating conditions: tight footprints, variable parcel rates and paths, and the need to upgrade without pausing sortation.

Recent logistics analyses underscore this industry shift, noting that operations increasingly choose service‑oriented, incremental automation investments instead of committing to single‑phase, high‑CapEx projects. The appeal is simple:

1. Phased deployment without shutting the building down

Industry case studies highlight retrofit strategies executed zone by zone, often over weekends or short maintenance windows. Instead of replacing entire lines, modular equipment sections are swapped, extended, or rerouted with minimal operational interference.

2. Faster integration with legacy WMS, WCS, and WES systems

Technology publications have emphasized the importance of flexible integration patterns (“black box,” “grey box,” and “white box” approaches) that let operators plug in new hardware without destabilizing upstream systems. Modular sortation fits neatly into this model by focusing on standardized interfaces, predictable PLC logic, and drop‑in equipment footprinting.

3. Configurable for any facility footprint

Reports from automation analysts show that many hubs operate in constrained legacy buildings. Modular units can navigate these constraints by adapting to difficult angles, multi‑level layouts, mezzanines, or irregular building geometry.

4. Scalable throughput, not fixed throughput

Across the industry, operators are shifting from “build for peak” to “build for flexibility.” Modular sorters can start small, such as with a single divert line, a modest table, a simple merge, and scale to full‑line systems as volume grows.

5. Lower operational risk

A major theme across modernization case studies is reducing risk during transitions. With modular deployments, new systems can run parallel to old systems until operators validate performance, then cutover in controlled phases.

How Leaders Modernize Without Downtime: The New Retrofit Playbook

Across recent modernization efforts, a consistent playbook has emerged. Logistics engineering teams regularly cite these five best practices when modernizing active parcel operations:

1. Replace in sections, not systems

Instead of decommissioning an entire conveyor line, modular sections are swapped out one at a time. Industry practitioners emphasize that this “progressive deployment” model vastly reduces the risk of delays.

2. Use dual‑running to de‑risk cutover

Many operators mirror scans, divert logic, or routing data to both the legacy and new systems during a test window. This dual state lets teams validate flow, destination accuracy, and throughput before flipping over to the new line.

3. Involve software integration early

WES/WCS specialists highlight that many modernization failures stem not from mechanical errors but from mismatched data flows. Bringing software teams in early prevents bottlenecks, no‑reads, and exception mishandling.

4. Leverage digital simulation and emulation

Modern integrators increasingly use simulation models to test lane behavior, gapping logic, divert patterns, and peak‑hour loads, reducing the chance of surprises during launch.

5. Optimize energy and sustainability as part of modernization

Industry research into sustainable warehouse automation shows a shift toward:

Energy‑efficient DC motor systems

Variable frequency drive (VFD) logic

Power‑down behaviors during low flow

Predictive maintenance for reduced energy waste

These measures are now standard procurement considerations, not optional add‑ons.

“Across the industry, operators are shifting from ‘build for peak’ to ‘build for flexibility.’ Modular sorters can start small, such as with a single divert line, a modest table, a simple merge, and scale to full‑line systems as volume grows.”

Where SmartSort Fits: A Modular Platform for the Modern Hub

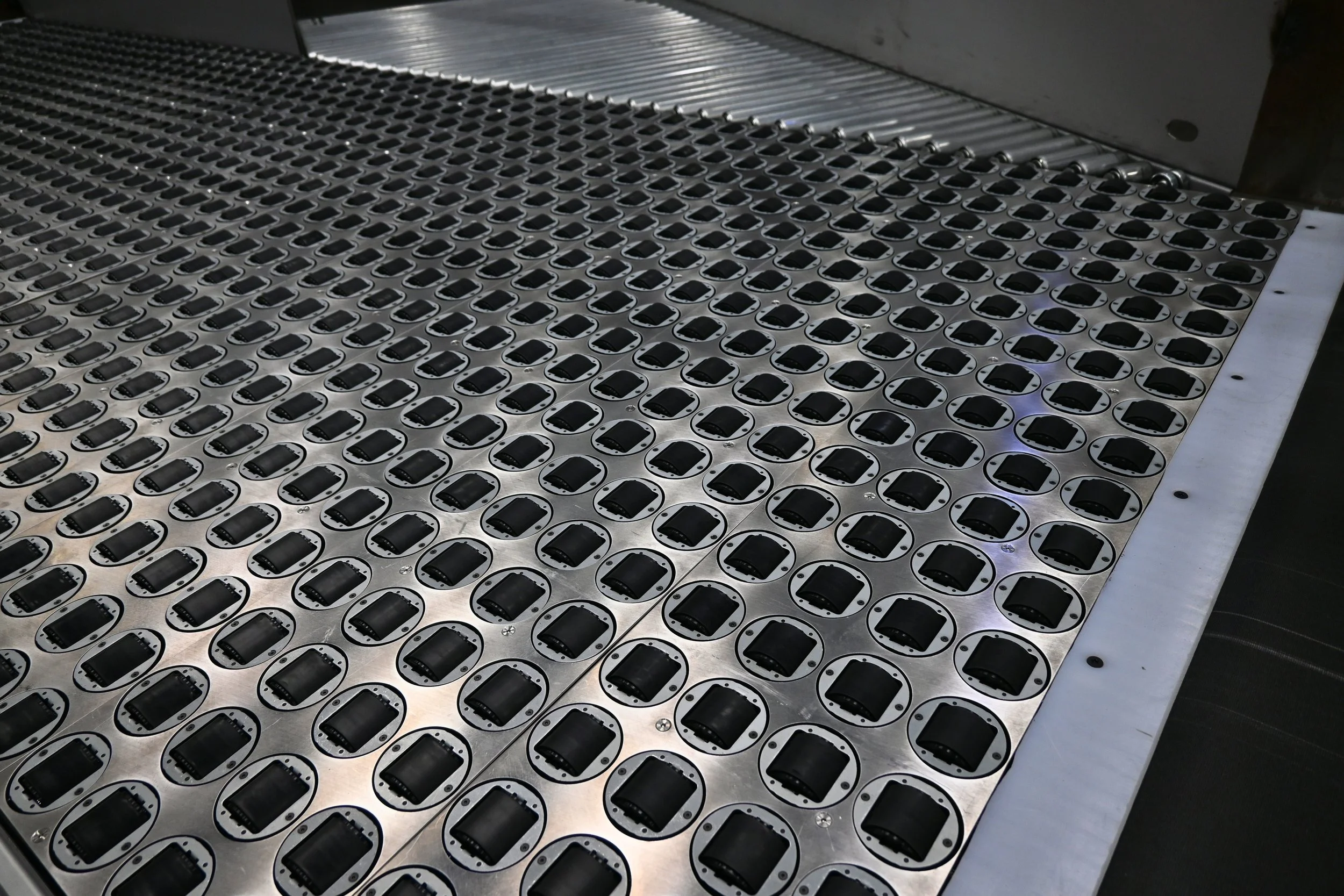

SmartSort — our modular, steerable‑wheel sortation platform — was engineered specifically for environments where downtime isn’t acceptable. Industry comparisons of wheel‑based sortation highlight the benefits of independent motor control, bidirectional diverting, and high handling accuracy for today’s parcel mix.

SmartSort’s modular table‑based architecture enables:

Pinpoint divert control for cartons, bags, and irregulars

Scalable table sizes, built in small blocks that can be added as needed

Rapid installation and reconfiguration

Minimal structural changes, making it ideal for brownfield retrofits

We’ve seen customers deploy SmartSort in high‑volume parcel hubs, regional consolidation centers, and specialized verticals, all using modular buildouts that minimize facility downtime.

But again, the technology is only one piece. The modernization model is the real transformative force.

Where the Industry is Heading Next

Based on recent logistics trend analyses, three shifts are defining the future of parcel and product movement:

1. Modularity becomes the default design philosophy

Operators want to build with “blocks,” not “buildings.” Modularity reduces risk, reduces CapEx spikes, and helps teams reconfigure equipment as parcel profiles evolve.

2. Software orchestration will drive the biggest gains

As WES, WCS, and AI‑based optimization systems advance, sorters will rely less on physical over‑engineering and more on precision software logic to manage peaks.

3. Cross‑vertical convergence

Parcel hubs, healthcare logistics networks, retail DCs, and 3PLs are beginning to operate with similar constraints: compressed SLAs, shrinking footprints, and fluctuating flows. Modular sortation fits all of them.

Modernization Without Disruption: Turning Complexity Into Advantage

The new era of parcel logistics demands systems that evolve as fast as customers' expectations. The harsh reality is that network transformation can’t pause operations, even for a day. But industry‑wide evidence, from large carriers consolidating networks to high‑growth fulfillment operations managing unpredictable order volumes, shows that modular sortation enables progress without compromising performance.

At Aegis Sortation, we believe modernization should feel controlled, strategic, data‑backed, phased, and above all, uninterrupted.

Your facility deserves a path forward that doesn’t require a full reset.

Ready to Take the Next Step with Modular Automation?

If you’d like to see how you can benefit from modular automation, reach out to us today for an expert consultation. From our proprietary solutions to our industry-leading service and systems integration capabilities, we’re here to help maximize your uptime as you work to future-proof your network.