Automated Smalls Bagging (ASB) - The Future of Parcel Automation

What is Automated Smalls Bagging?

Automated Smalls Bagging (ASB) is an end-to-end automated solution that leverages a range of innovative technologies to streamline conveyance, sortation, and containerization throughout your facility.

Ideal for parcel, warehouse, and e-commerce industries, ASB enables you to do more with less by drastically reducing mis-sort rates and reducing manual labor costs by over 50%.

From inbound to outbound, Aegis’ Automated Smalls Bagging solution transforms your fulfillment flow by automating every step in the bagging process. It eliminates bottlenecks, accelerates throughput, and ensures every package gets safely to its destination.

Whether you're scaling operations or solving labor challenges, ASB delivers unmatched precision and performance at speed.

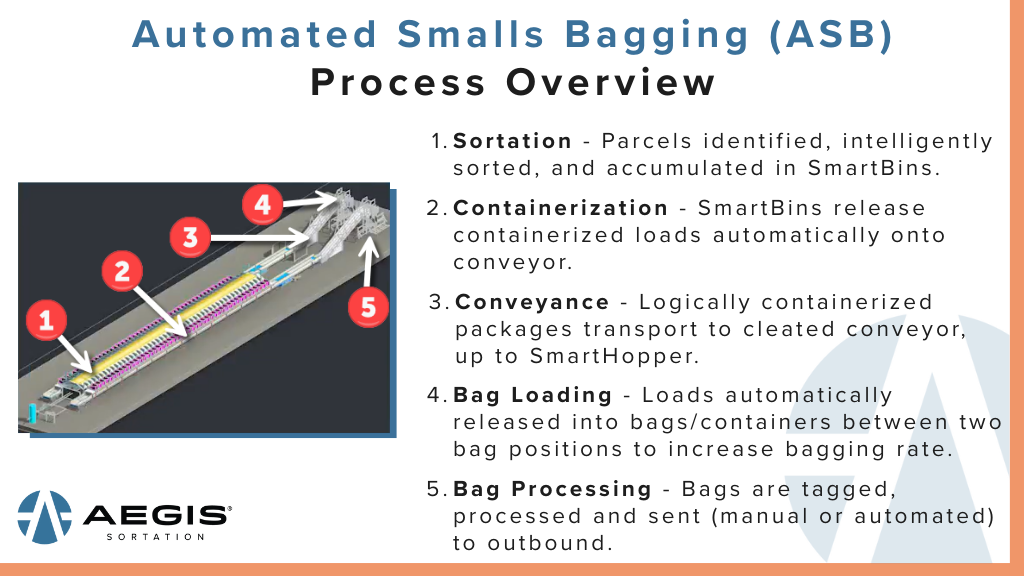

Automated Smalls Bagging Process

Aegis Sortation’s Automated Smalls Bagging system transforms parcel operations by automating each stage of the bagging and containerization process. When paired with our SmartDock, SmartBagger, SmartKart, and Smart De-bagger systems, it maximizes your return on investment while ensuring seamless operations.

Sortation: A high-speed, automated sortation system, such as our sliding shoe sorter, identifies parcels and intelligently sorts them into SmartBins.

Containerization: Sensors detect when the bin reaches capacity, and the containerized loads are automatically released onto a conveyor.

Conveyance: The packages move along a cleated conveyor, up to the SmartHopper .

Bag Loading: Available in 2-way and 3-way configurations, the Smart Hopper automatically releases loads directly into bags at workstations.

Bag Processing:

Aegis SmartDock: Handles up to 25 bags and is maneuvered manually by an associate or automatically using a SmartKart to the next stage.

Aegis SmartBagger: Automatically stages, opens, tenders, zips, labels, and transports bags to optimize operations.

ASB Key Benefits

Automated Sortation & Containerization: Smalls are organized by destination, vastly reducing manual handling and inefficiencies. This streamlined process accelerates throughput, helping you meet loading and package-per-hour goals.

Queued and Consolidated Workflow: Packages move seamlessly through the system, minimizing errors and re-work. The end-to-end process enables optimal resource management, keeping operations running at peak efficiency.

Real-Time Performance Statistics: ASB tracks system performance and delivers actionable insights, enabling your teams to monitor key metrics, identify bottlenecks, and make data-driven improvements to stay ahead of productivity standards.

Sorter Mis-sort Detection: Integrated label identification and scanning detect mis-sorts early, reducing costly re-work and reducing the likelihood of service failures.

Simplistic Mechanical Design: Reduces downtime and cost of ownership by leveraging fewer and less complex components.

Check Out Our Blog: From Manual to Automated: Overcoming the Top Challenges in Parcel Sortation

Explore More Insights

Stay ahead with fresh perspectives on automation, sortation, and conveyor innovation. Check out our latest blog posts and resources designed to help you make smarter decisions.