The Evolution of Inbound Logistics: How Modern Automation Transforms Dock Unloading

Inbound sortation is the heartbeat of every parcel and distribution center. It’s where speed, accuracy, and safety converge to determine how efficiently goods move from dock to destination. As e-commerce continues to reshape the industry, facilities are under mounting pressure to process higher volumes, manage diverse package types, and meet ever-tightening delivery windows. Yet, many operations still rely on manual unloading and sorting, a reality that brings persistent operational challenges.

Before exploring how automation and modern conveyor systems can transform parcel handling, it’s essential to understand the pain points that drive the need for change. From rising labor costs and workforce shortages to safety risks and space constraints, the following section dives into the real-world obstacles that facilities face every day, and why solving them is critical for long-term success.

The Realities of Inbound Sortation: Pain Points and Operational Challenges

1. Labor Costs and Workforce Shortages

Parcel and distribution centers have long relied on manual labor to unload trailers and sort packages. This approach, while flexible, is increasingly unsustainable. Labor costs continue to rise, and the industry faces chronic shortages of skilled workers. According to recent studies, job openings for loading and stocking roles have surged nearly 97% since 2020, yet the available workforce has not kept pace. Turnover rates remain high, forcing facilities to spend more on recruitment, training, and overtime. The result is a persistent strain on operational budgets and a growing need for solutions that reduce dependency on manual labor.

2. Throughput Bottlenecks and Efficiency Gaps

Manual unloading and sortation often struggle to keep up with the demands of modern parcel volumes, especially during peak periods. Facilities designed decades ago for lower volumes now face spikes driven by e-commerce, with more frequent, smaller orders and a wider variety of packaging types. Bottlenecks can occur at multiple points: dock doors, conveyor merges, and sortation zones. These slowdowns lead to missed service-level agreements, increased overtime, and delayed shipments. Even minor inefficiencies, such as misaligned handoffs or inconsistent conveyor speeds, can cascade into major operational disruptions.

3. Safety Risks at the Dock Door

Loading docks are among the busiest and most hazardous areas in any warehouse. The constant movement of trucks, forklifts, and personnel creates a high risk of accidents. Common hazards include falls from dock edges, collisions between vehicles and workers, and injuries from lifting heavy or awkward packages. OSHA reports that 25% of all warehouse injuries occur at or near the loading dock. Safety concerns are compounded by visibility issues, noise, and the pressure to unload quickly. Facilities must balance speed with strict safety protocols to protect workers and maintain operational continuity.

4. Package Variety and Irregulars

The explosion of e-commerce has led to a dramatic increase in the diversity of package types: polybags, bubble mailers, oversized boxes, and non-conveyables. This variety poses significant challenges for both manual and automated sortation systems. Irregularly shaped or damaged packages can jam conveyors, require special handling, or slow down the entire process. Facilities must design their parcel handling solutions to accommodate a wide range of sizes, weights, and packaging materials, often within the constraints of existing infrastructure.

5. Space Constraints and Facility Footprint

Many distribution centers operate in legacy buildings with limited space for expansion. As parcel volumes grow, facilities face overcrowding, inefficient layouts, and storage challenges. Space constraints can lead to longer pick times, delayed shipments, and increased safety risks. Optimizing the use of available space through vertical storage, modular automation, or reconfigured workflows is essential for maintaining throughput and controlling costs.

6. Technology Limitations and Integration Challenges

While robotic unloaders and automated conveyor systems offer promise, they are not a perfect solution for every application. Current technology struggles with loose-loaded trailers, irregular packages, and unpredictable stacking patterns. Robots may require controlled environments, consistent lighting, and standardized packaging to operate efficiently. Integration with existing systems can be complex, requiring specialized expertise and careful planning to avoid disruptions. Facilities must weigh the benefits of automation against the realities of their operational environment and the limitations of available technology.

7. Accuracy and Error Rates

Sortation accuracy is critical for meeting customer expectations and controlling costs. Manual processes are prone to human error, especially under pressure. Mis-sorted packages lead to delays, rework, and dissatisfied customers. Automated conveyor and sortation systems can dramatically improve accuracy, but only if they are properly calibrated and maintained. Facilities must invest in robust identification hardware (scanners, cameras), real-time data integration, and regular system audits to ensure consistent performance.

8. Operational Resilience and Downtime

Unplanned downtime, whether from equipment failures, staffing gaps, or safety incidents, can disrupt service and operations. Facilities must build resilience into their parcel-handling solutions through proactive maintenance, adaptable approaches, and contingency plans for peak periods and unexpected disruptions. Modular, scalable systems allow operators to adapt quickly and maintain service levels even under challenging conditions.

9. Customer Feedback and Service Expectations

Customers expect fast, accurate, and reliable delivery. Delays, errors, or damaged packages can erode trust and impact repeat business. Facilities must gather and act on customer feedback to identify service gaps, improve processes, and stay competitive. Real-time tracking, transparent communication, and continuous improvement are essential for meeting evolving expectations in parcel handling solutions.

10. Regulatory Compliance and Sustainability

Increasingly, parcel and distribution centers must comply with safety, environmental, and labor regulations. Sustainability goals, such as reducing energy consumption or minimizing waste, add another layer of complexity. Automated conveyor and sortation systems can support compliance by standardizing processes, improving traceability, and enabling more efficient use of resources.

“According to recent studies, job openings for loading and stocking roles have surged nearly 97% since 2020, yet the available workforce has not kept pace.”

Why These Pain Points Matter

These operational realities shape every decision in inbound sortation. Facilities must balance speed, accuracy, safety, and cost while adapting to changing parcel volumes, packaging types, and customer expectations. The right parcel handling solutions can help overcome these challenges, but only if they are designed with a deep understanding of the pain points and constraints unique to each operation.

Overcoming Inbound Sortation Challenges with Automated Conveyor and Sortation Systems

1. Reducing Labor Dependency and Costs

Automated conveyor and sortation systems are designed to minimize the need for manual unloading and sorting. By automating repetitive, physically demanding tasks, facilities can reduce labor costs, lower turnover, and free up skilled workers for higher-value activities. These systems can operate continuously, helping facilities manage peak volumes without the need for additional staffing or overtime. The result is a more stable, predictable cost structure and improved operational resilience.

2. Boosting Throughput and Efficiency

Modern parcel handling solutions leverage high-speed conveyors, advanced sortation algorithms, and real-time data integration to maximize throughput. Automated systems can process thousands of packages per hour, far exceeding manual capabilities. By streamlining the flow of goods from dock to distribution, facilities can meet tight service-level agreements, reduce dwell times, and improve customer satisfaction. Bottlenecks at dock doors and sortation zones are minimized, enabling faster receiving and order fulfillment.

3. Enhancing Safety at the Dock Door

Safety is a critical concern in inbound sortation. Automated conveyor and sortation systems help mitigate risks by reducing the number of workers exposed to hazardous dock environments. Features such as automated package detection, controlled conveyor speeds, and integrated safety sensors can help create safe working environments. These systems also support compliance with industry regulations, helping facilities maintain a strong safety record and protect their workforce.

4. Handling Package Variety and Irregulars

One of the strengths of automated sortation systems is their ability to handle a wide range of package types, including irregularly shaped or non-conveyable items. Advanced identification technologies, such as vision systems, barcode scanners, and weight sensors, enable precise sorting and routing. Modular automation allows facilities to adapt quickly to changing package profiles, ensuring consistent performance even as e-commerce continues to drive diversity in parcel sizes and formats.

5. Optimizing Space and Facility Footprint

Space constraints are a common challenge in parcel and distribution centers. Automated conveyor and sortation systems can be configured to fit existing layouts, making use of vertical space and compact footprints. Modular designs allow for phased implementation, enabling facilities to scale automation as needs evolve. This flexibility helps operators maximize throughput without costly infrastructure changes or expansions.

6. Overcoming Technology Limitations

While no system is perfect, ongoing advances in robotics, machine learning, and sensor technology are expanding the capabilities of automated unloading and sortation. Solutions are now available that can handle loose-loaded trailers, mixed package types, and unpredictable stacking patterns. Integration with warehouse management systems (WMS) and real-time analytics ensures seamless operation and continuous improvement.

7. Improving Sortation Accuracy

Automated conveyor and sortation systems deliver consistently high accuracy rates, reducing errors and rework. Real-time tracking, automated identification, and intelligent routing ensure that each package reaches its correct destination. Facilities benefit from fewer mis-sorts, faster exception resolution, and improved customer satisfaction.

8. Building Operational Resilience

Automation supports operational resilience by enabling facilities to maintain service levels during peak periods, staffing shortages, or unexpected disruptions. Proactive maintenance, remote monitoring, and flexible workflows help minimize downtime and keep operations running smoothly.

9. Supporting Regulatory Compliance and Sustainability

Automated systems can help facilities meet regulatory requirements for safety, labor, and environmental impact. Energy-efficient designs, optimized workflows, and reduced waste contribute to sustainability goals, supporting both compliance and corporate responsibility.

Best Practices for Implementing Automated Conveyor and Sortation Systems

1. Assessing Facility Needs and Constraints

Successful automation begins with a thorough assessment of your facility’s current operations, pain points, and future goals. Key considerations include:

Parcel Volume and Mix: Analyze historical and projected parcel volumes, package types, and peak periods to determine system requirements.

Space and Layout: Map out available floor space, dock configurations, and existing workflows. Identify bottlenecks and areas where automation can have the greatest impact.

Labor and Safety: Evaluate current staffing levels, safety records, and training needs. Consider how automation can reduce risk and support workforce development.

2. Process Mapping and Workflow Optimization

Before selecting technologies, it’s essential to map out your inbound sortation process from trailer unload to final sortation. This includes:

Unloading Methods: Decide whether robotic unloaders, extendable conveyors, or hybrid solutions best fit your operational realities.

Sortation Zones: Define primary and secondary sortation areas, and determine how packages will be routed through each stage.

Exception Handling: Plan for irregulars, damaged packages, and non-conveyables, ensuring your system can adapt to real-world variability.

3. Technology Selection and System Design

Choose automated conveyor and sortation systems that align with your facility’s needs and constraints. Consider:

Modular Automation: Opt for systems that can be scaled and reconfigured as parcel volumes and business needs evolve.

Integration Capabilities: Ensure new technologies can interface with existing warehouse management systems (WMS), identification hardware, and data analytics platforms.

Safety Features: Prioritize systems with built-in safety sensors, emergency stops, and compliance with industry standards.

4. Simulation, Testing, and Phased Implementation

Minimize disruption by simulating new workflows and testing system performance before full deployment. Best practices include:

Digital Twins and Simulation: Use modeling tools to visualize system performance, identify bottlenecks, and optimize layouts.

Pilot Programs: Start with a pilot in a single zone or dock area, gather feedback, and refine processes before scaling up.

Phased Rollout: Implement automation in stages, allowing for training, troubleshooting, and continuous improvement.

5. Training, Support, and Continuous Improvement

Automation is most effective when paired with robust training and ongoing support. Key steps:

Hands-On Training: Provide staff with practical training on new equipment, safety protocols, and exception handling.

Service and Maintenance: Establish proactive maintenance schedules and support plans to minimize downtime.

Performance Monitoring: Track key metrics, such as throughput, accuracy, safety incidents, and use data to drive ongoing improvements.

The Role of a Trusted Systems Integration Partner

Transitioning from manual to automated inbound sortation is a complex process that benefits from expert guidance. A trusted partner can:

Provide End-to-End Project Management: From initial assessment and process mapping to system design, installation, and go-live support.

Deliver Custom Engineering Solutions: Tailor automation to your facility’s unique needs, parcel mix, and operational goals.

Offer Advanced Software Integration: Ensure seamless communication between new systems and existing platforms.

Support Safety and Compliance: Help maintain a safety-first culture and meet regulatory requirements.

Enable Rapid, Scalable Growth: Design solutions that adapt to changing business needs and support long-term success.

How Aegis Sortation Delivers Seamless Integration and Lasting Results

End-to-End Consultation and Integration

Aegis Sortation stands out as a trusted partner for parcel and distribution centers seeking to automate inbound sortation. Our approach begins with a deep dive into your facility’s unique challenges, including parcel mix, space constraints, labor realities, and safety goals. We leverage decades of material handling and logistics experience to map processes, optimize workflows, and design solutions that fit your operational environment.

Custom Engineering and Modular Automation

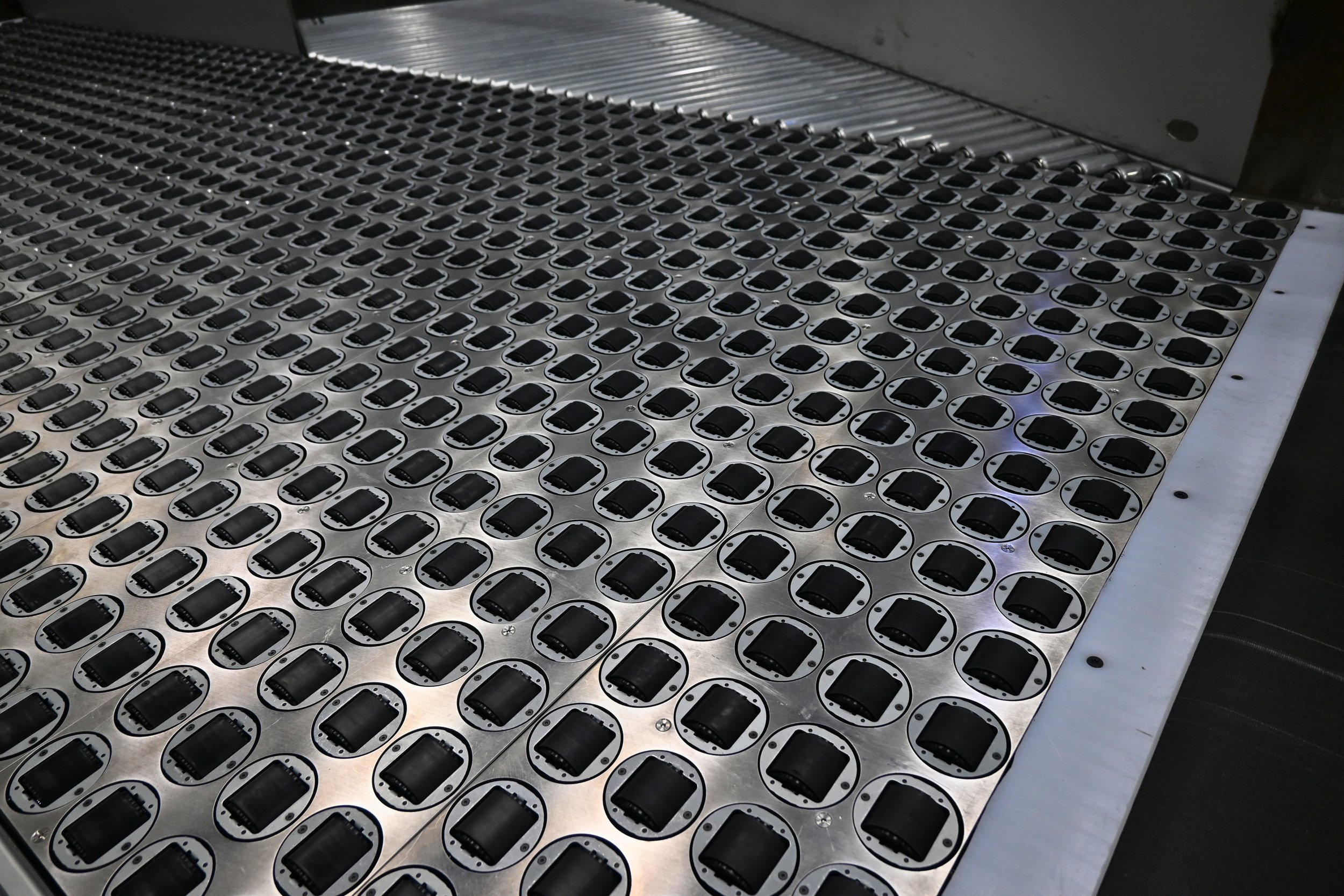

Our engineering team specializes in custom equipment design and modular automation, ensuring that every solution is tailored to your needs. Whether you’re integrating robotic unloaders, automated conveyor and sortation systems, or hybrid workflows, Aegis delivers scalable, flexible systems that grow with your business. Our SmartSort technology, for example, adapts to a wide range of package types and sortation requirements, supporting both primary and secondary sortation zones.

Advanced Software Integration and Controls

Aegis provides advanced software integration, connecting new automation with your existing warehouse management systems, identification hardware, and analytics platforms. Our controls expertise ensures seamless communication, real-time tracking, and intelligent routing, driving accuracy and efficiency across your operation.

Safety-First Culture and Compliance

Safety is the foundation of every Aegis installation. We maintain strict compliance with industry standards and have a reputation for safe, reliable service at jobsites. Our training programs, technologies, and hands-on support help reduce the likelihood of incidents and ensure a smooth transition to automated workflows.

Dedicated Support and Continuous Improvement

From concept to commissioning and beyond, Aegis offers comprehensive training, proactive maintenance, and 24/7 service support. Our customer-first mindset means we’re always available to troubleshoot, optimize, and help you adapt to changing business needs. We measure success by your operational results, such as throughput, accuracy, safety, and customer satisfaction.

Conclusion

Automating inbound sortation is a strategic investment that pays dividends in efficiency, safety, and scalability. By partnering with Aegis Sortation, you gain access to industry-leading expertise, custom engineering, and dedicated support—ensuring your transition to automated conveyor and sortation systems is seamless and successful.

Ready to take the next step?

Contact Aegis for a demo or consultation and discover how our proprietary solutions and automated material handling systems can help you achieve your goals.